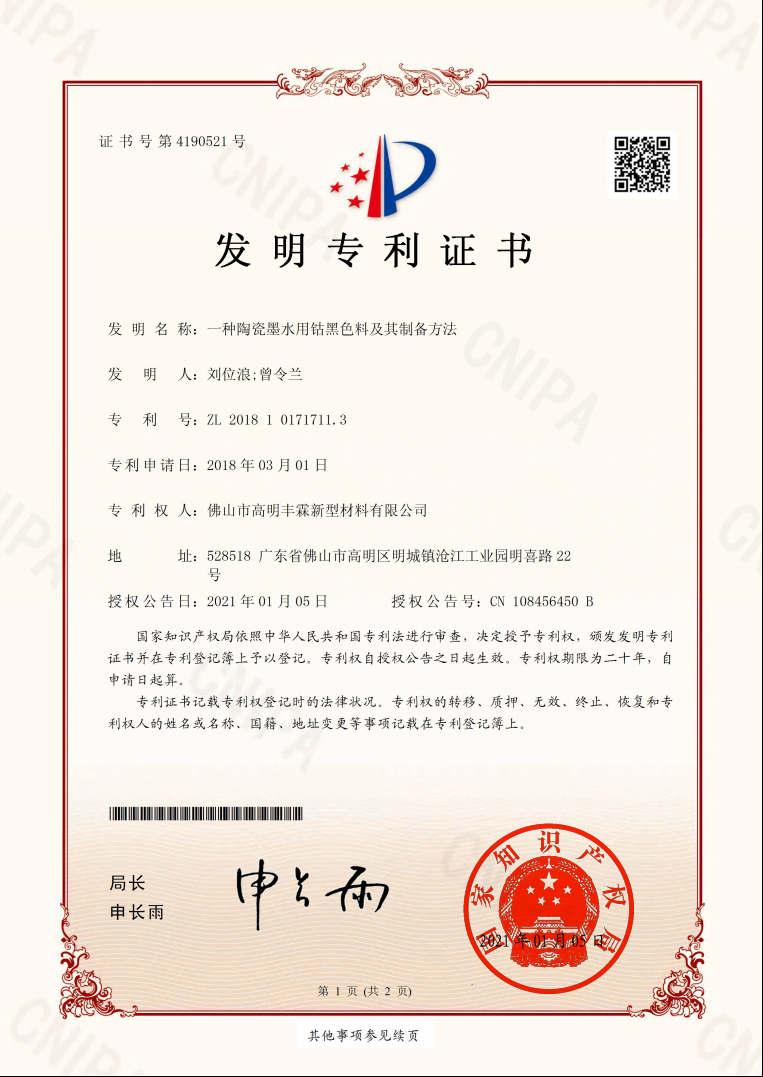

Our company has once again obtained a national invention patent authorization

Release Time:March,03,2021 VIEW:2388

A few days ago, the company once again obtained an invention patent authorized by the State Intellectual Property Office. The name of the patent is "a cobalt black material for ceramic ink and its preparation method", and the patent number is ZL201810171711.3.

The invention discloses a cobalt black material for ceramic ink, which is made from the following raw materials according to weight percentage: Co3O4 35% 45%, NiO 15% 20%, Fe2O3 8% 15%, Cr2O3 20% 30% . In the present invention, an ideal colorant ingredient formula range and a colorant preparation method are obtained through a large number of experiments, and the obtained cobalt black material has full color, pure color tone and low magnetism.

The invention relates to the technical field of ceramic materials, in particular to a cobalt black material for ceramic ink and a preparation method thereof.

Cobalt black material is popular with people for its solemn, elegant tone and solemn decorative effect. Although the price is high, it is still widely used in the field of architectural decoration, and the amount of color material is extremely large.

Inkjet printing technology is a non-contact digital printing technology developed successfully in the late 1970s. It sprays ink onto the surface of various media through nozzles on the print head, realizing non-contact, high-speed, low-noise monochrome or color text or image printing. At the beginning of the 21st century, the American FERRO company developed oil-based inks suitable for inkjet printing on ceramics. Since then, after more than ten years of development, inkjet printing technology has been widely used in the field of architectural ceramics. As a brand-new ceramic decoration concept, the color printing technology for ceramic decoration can make full use of abundant computer data and introduce digital technology into traditional architectural ceramic products, so that ceramic decoration can keep up with the pace of the times and reflect fashionable characteristics and meet people’s personalities. The requirements of industrialization have pushed ceramic decoration technology to a new stage.

With the progress of ceramic ink localization, the production cost of ceramic inkjet printing technology applied to ceramic tiles has been lower than traditional screen printing technology and rubber roller printing technology. Ceramic inkjet printing technology has unparalleled practicality in production. Sex and flexibility, which provide a broader space for the popularization of inkjet printing technology, and further squeeze the market share of traditional ceramic pigments.

When traditional cobalt black materials are used to prepare ceramic inks, they have weak color development, impure hue, and large magnetism. When used on inkjet machines, they will cause problems such as drawing lines and dripping ink, which affects the continuity of inkjet printers. In production, there are still big problems in the application of black pigments.

Summary of the invention

In order to make up for the defects of the prior art, the present invention provides a cobalt black material for ceramic ink and a preparation method to make the cobalt black material have the characteristics of full color development, pure color tone, and low magnetism.

The technical problem to be solved by the present invention is achieved through the following technical solutions: a cobalt black material for ceramic ink, according to weight percentage, made of the following raw materials: Co3O4 35%-45%, NiO 15%-20%, Fe2O3 8% _15%, O2O3 20%_30%.

Further, the particle size D100 of the above-mentioned raw materials is less than 10um.

After the calcined product is crushed, the ball mill is used for ultra-fine processing to obtain the cobalt black material.

The chromaticity value of the cobalt black material is L*=16-18.5, a*=0.1-0.5, b*=0.05-0.25. The present invention has the following beneficial effects: The present invention obtains an ideal colorant ingredient formula range and colorant preparation method through a large number of experiments, and the obtained cobalt black colorant has full color, pure color tone and low magnetism.

Our R&D personnel have been committed to improving the R&D and innovation of product color, optimizing product performance, and providing customers with more competitive products.